1.1 Engineering Design Deep Dive Videos

1. What was the problem the engineers at IDEO were asked to solve?Taking something old and familiar like a shopping cart and completely redesigning it within a time limit of 5 days.

2. Name two constraints that they had to deal with.A time limit of 5 days.No title to work with so as to be organized.

3. What were two of the major concerns/issues the teams discovered from their research?There were 22 thousand child injuries a year after usage of the old shopping cart. Theft of shopping carts.

4. IDEO uses several methods, processes and ideas to generate alternative solutions. What two principles or approaches appealed to you the most? Why?To not criticize any (wild) ideas.Mottos like ‘encourage wild ideas’ were pasted all around their working place.Both of these approaches encourages creativity and innovativeness that allows the birth of new fresh ideas that solves difficult problems.

5. How were the possible solutions prototyped and tested?The group was separated into 4 different teams and were asked to come up with a prototype focused on solving one problem. The main ideas from the sub-prototype were reused to a mini prototype design that was later brought to life by real mechanics.

6. Was there a redesign step in the IDEO project? What was the final outcome? Yes. The final outcome was a 90 degree rotatable cart that held shopping baskets and were able to hold children safely. Also, the baskets were to be left at the shopping malls and the shopped items to be hung on hooks on the cart.

1.2 Assignments of Roles

Project Manager (IC of the report and presentation) : Sanjana Suha

Responsible for all documentation and “care” of the mousetrap.

Insures that all tasks are completed and documented on time.

Has final say on any issue that cannot be settled by consensus

Drivetrain Engineer (IC of the Analysis) : Greg Lim

Responsible for developing system to transfer energy from the “engine” to the wheels.

Insures proper testing and documentation of all drivetrain components.

Wheel Engineer (IC of the Construction and Testing) : Teo Ji Hao

Responsible for wheel choice and design

Sources materials for wheels

Works with Drivetrain Engineer to determine wheel-to-axle ratio and attachment

Chassis Engineer (taken by the 3rd member if it is a 3-member team) : Teo Ji Hao

Responsible for the look and function of the body (chassis) of the car

Sources all materials for the chassis

Works with Drivetrain and Wheel Engineers to insure function and look of wheels and drivetrain components

1.3 Brainstorming

Engineering Goals

1. What was the problem the engineers at IDEO were asked to solve?Taking something old and familiar like a shopping cart and completely redesigning it within a time limit of 5 days.

2. Name two constraints that they had to deal with.A time limit of 5 days.No title to work with so as to be organized.

3. What were two of the major concerns/issues the teams discovered from their research?There were 22 thousand child injuries a year after usage of the old shopping cart. Theft of shopping carts.

4. IDEO uses several methods, processes and ideas to generate alternative solutions. What two principles or approaches appealed to you the most? Why?To not criticize any (wild) ideas.Mottos like ‘encourage wild ideas’ were pasted all around their working place.Both of these approaches encourages creativity and innovativeness that allows the birth of new fresh ideas that solves difficult problems.

5. How were the possible solutions prototyped and tested?The group was separated into 4 different teams and were asked to come up with a prototype focused on solving one problem. The main ideas from the sub-prototype were reused to a mini prototype design that was later brought to life by real mechanics.

6. Was there a redesign step in the IDEO project? What was the final outcome? Yes. The final outcome was a 90 degree rotatable cart that held shopping baskets and were able to hold children safely. Also, the baskets were to be left at the shopping malls and the shopped items to be hung on hooks on the cart.

1.2 Assignments of Roles

Project Manager (IC of the report and presentation) : Sanjana Suha

Responsible for all documentation and “care” of the mousetrap.

Insures that all tasks are completed and documented on time.

Has final say on any issue that cannot be settled by consensus

Drivetrain Engineer (IC of the Analysis) : Greg Lim

Responsible for developing system to transfer energy from the “engine” to the wheels.

Insures proper testing and documentation of all drivetrain components.

Wheel Engineer (IC of the Construction and Testing) : Teo Ji Hao

Responsible for wheel choice and design

Sources materials for wheels

Works with Drivetrain Engineer to determine wheel-to-axle ratio and attachment

Chassis Engineer (taken by the 3rd member if it is a 3-member team) : Teo Ji Hao

Responsible for the look and function of the body (chassis) of the car

Sources all materials for the chassis

Works with Drivetrain and Wheel Engineers to insure function and look of wheels and drivetrain components

1.3 Brainstorming

Engineering Goals

Develop a MouseTrap Car with the following specifications:

- (a) Uses only the MouseTrap provided as the only energy source

- (b) Has a maximum length of 30 cm, with of 10 cm, and a height of 10 cm

- (c) Can travel a minimum distance of 5 meters carrying an egg (the egg will be provided by the teacher)

- (d) All time-lines have to be adhered

- (e) Aerodynamic shape for speed

- (f) Usage of easily accessible materials

- (g) Presence of energy securing device (to stop energy from immediately being released)

- (h) Ensure that the model is stable

Design Ideas

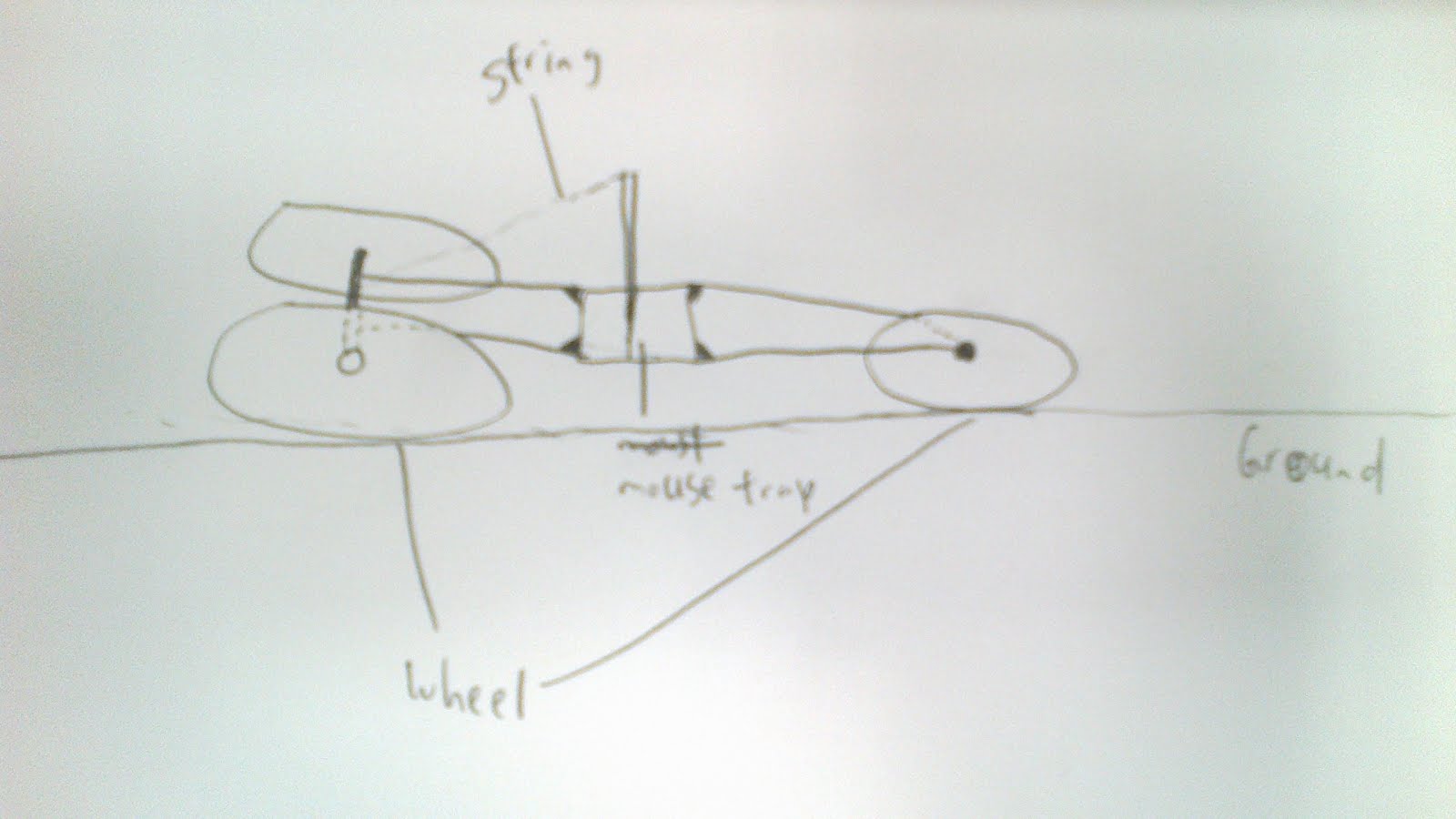

1st Idea:

2nd Idea:

3rd Idea:

1.4 Decision Making Matrix

1.5 Design Rationale and Notes

Wheels

With three-wheeled cars, it will be easier to adjust the steering of the vehicle because there are fewer wheels to be aligned. The advantage of using four wheels is the car will have much more stability.

Larger wheels have larger diameter so they have to turn fewer times to cover a certain distance compared to smaller wheels.

Lever arm

The distance from the turning axis to the point of contact is called the lever arm. By adjusting the length of the mouse trap’s lever arm, the force that is applied to the wheels of your car can be varied. Long lever arms decrease the pulling force while short arms increase the pulling force. The longer the length of the lever arm used, the more the string can wind around the drive axle. Therefore, a greater overall travel distance can occur as the string is pulled off the drive axle. Lever arms should not extend past the axle when in the lowered position. For correct lever arm length it should be ensured that the lever reaches the axle. If the lever end is L-shaped then it will center the string on the axle.

Chassis Material

Chassis must not be too light because it will cause the car to be too fragile but it cannot be too heavy since extra mass will slow down the car as more force will be required.(F=ma)The frame must be light-weight but strong. Light Balsa wood, pine, or bass wood can be used to build the chassis but balsa wood is somewhat brittle and hard to drill holes into without ripping. Materials like styrofoam, corrugated cardboard, plastics, aluminum can be used as well since these are light-weight and strong.

Chassis Shape

The shape is mostly rectangle-based for ensuring stability and the mass has been reduced to make it as light as possible so that more acceleration can be achieved. The frame must be stiff and strong at the same time not bulky.

Location of Mousetrap

The mousetrap should be placed in the middle of the wheels on the front and back for easy access and maximized space usage.

Axles

A large wheel with a small axle will allow the car to cover more distance per turn of the axle. Axles can be successfully made from just about any “rod” type material. Straws, skewers, pencils (round not hex-shaped), dowels, hangers. The wheels must be securely attached to the axles. To build distance vehicles, a small force over a long distance is idealized; therefore, using a large wheel with a small axle is the key.

String type and attachment

The string must be strong to be able to handle the strength of the pulling force and still not snap. Using a string that is too thick, will cause it to not wind around the drive axle smoothly, making the pulling force inconsistent.

The string cannot be tied to the axle as it will begin to rewind itself and make the car come to a stop. However, the team will tie the string to the drive axle so as to ensure that winding the string around it is a much easier task.

1.6 Materials used

No comments:

Post a Comment